Request A Quote

Atlas Products

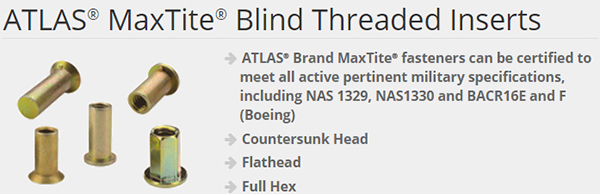

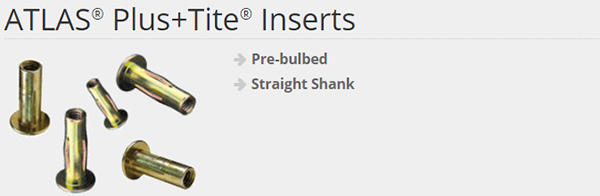

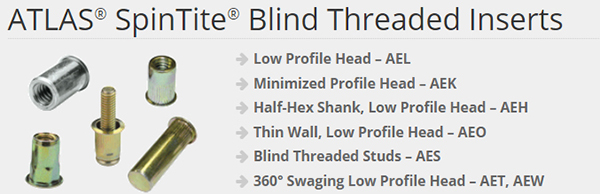

The Atlas® product line includes two basic types of threaded rivet-nut products. The Atlas SpinTite® product line includes a variety of inserts which satisfy most applications where strong one side thread installation is required. In addition, Atlas offers the MaxTite® brand of Rivet-Nut products which are generally thicker headed and heavier walled for the most demanding high performance applications. Of course if a standard product does not fit your need, please contact us so that we can make other recommendations. We also offer cost effective and easy to use Installation tooling for our complete line of fasteners. Please review our installation tooling videos.

Online Catalog

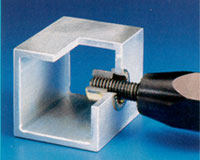

Installation Steps

1. The fastener is threaded on to the mandrel of the installation tool.

2. It is then inserted into the hole in the installation plate.

3. The head is held by the tool anvil and the mandrel of the tool drives into the fastener threads, shortening it to crimp it securely in place.

Installation Tools

Lightweight, Easy to operate tools for installing the complete line of Atlas™ SpinTite® and MaxTite® Fasteners

- Atlas™ Fastener Installation Tools

- AE 800 Series Spin/Spin Power Tools

- AE 45 Spin/Pull Power Tool

- L Series Manual Tools

SpinTite® and MaxTite® Installation Tips For Threaded Inserts

1) Prepare properly sized hole in sheet

2) Thread the fastener partially onto the tool mandrel. Insert the fastener completely into the hole, and then press the forward trigger. Hold the trigger until the tool stops and the fastener is fully installed.

3) Withdraw the tool by pressing the reverse trigger.

PDF Operating Instructions

L845/L722 Instructions 158 KB file

L845/L722 Instructions 158 KB file L6000 Instructions 72 KB file

L6000 Instructions 72 KB file RH160E Instructions 940 KB file

RH160E Instructions 940 KB file  RH140E Instructions 300 KB file

RH140E Instructions 300 KB file

Atlas Catalog

Atlas Catalog